PRODUCTS

Products

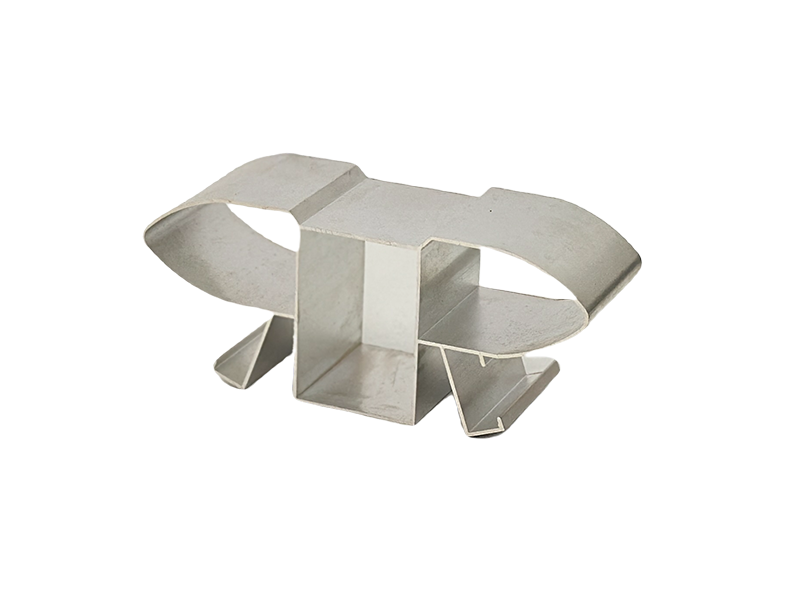

aluminum die casting

Aluminum die-casting can achieve high-efficiency and high-precision production, and can quickly form parts with complex structures to meet diversified design requirements. Secondly, the aluminum material itself has the characteristics of light weight, high strength, corrosion resistance, and good thermal conductivity, which makes the die casting have excellent physical properties and long service life.

automobile industry

Electronic communication equipment

Home Appliances and Electrical Equipment

Industrial machinery and equipment

Aerospace

architectural decoration

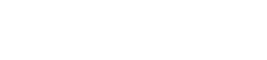

Aluminum tensile

The aluminum drawing process shows remarkable advantages. It can not only accurately shape complex and delicate geometric shapes to meet the designer's creative ideas, but also make full use of the lightweight and high-strength characteristics of aluminum to bring significant products. The weight reduction effect improves the overall performance and energy efficiency.

electronic industry

Transportation

Building

Aerospace

PROCESS

Customization process

Design the mold opening scheme according to the customer's 3D drawing, make the mold after the scheme is confirmed through negotiation, deliver the mold opening sample after the mold is completed, and mass production after the sample is confirmed to be qualified.

Confirm scheme

Design Development

Confirm sample

Mass production (OTS,SOP)

ABOUT US

About Us

Plant area

Number of employees

Annual capacity aluminum tensile

Main business

Hand plate proofing, die casting, extrusion die design and production, aluminum alloy high and low pressure casting and aluminum extrusion production, workpiece precision size processing. With oxidation, electrophoresis, dusting, painting and other integrated production enterprises, products covering the whole industry.

Main production equipment

There are 10 sets of die casting machines, 2 sets of liquid die forging, 3 extruders, 1 gravity casting machine, several numerical control lathes, CNC, turning and milling compound integrated machines, and are equipped with surface treatment workshop, anodizing workshop, painting workshop, powder spraying workshop, electrophoresis workshop, etc. The complete process chain is seamless.

Company Products

2000 tons of aluminum casting, 1000 tons of aluminum drawing, ADC12,A356, A380, other YL104,A360 ,AC46000,AlSi10MgMn, etc. Aluminum extrusion material brands 6063, 6061, 6082, etc.

ADVANTAGES

Enterprise advantage

01

The company's management team has many years of experience in auto parts development and production, and can effectively complete the development and production management of automotive aluminum alloy castings to meet customer requirements.

02

High vacuum die casting technology, the production of castings can be heat treated and meet customer requirements for porosity.

03

Able to assist customers in new product development and auxiliary design, so as to meet customers' expectations in product structure, function, manufacturability and cost.

MESSAGE

Online Message

BLOG

Blog